Thermal Lightweight Aggregate (TLA)

Super light aggregates for the manufacture of lightweight thermally insulating screeds

A Fast And Simple Way To Lay An Insulated Floor Or Roof Screed

The complete range of super light and high thermal insulating aggregates based on pre-coated virgin EPS beads with controlled density. Each bead is coated at production stage with EIA additive. This enables perfect mixing with the water and cement producing an homogeneous distribution of beads preventing beads surfacing or bonding together. Mix beads, cement and water.

Contact Corepro Systems in Devon today for Thermal Lightweight Aggregate (TLA) sub-base.

We supply customers throughout the UK.

Isolcap 250 Ready Mixed and Supplied In Bags. Just Add Water

Pre-mixed 50 litre bags containing coated EPS beads and cement. Simply mix with water, pour, spread and level.

20 bags = 1 cubic metre of insulating sub-base

Thermal efficiency

- Low thermal conductivity (λ).

- Perfect for use beneath underfloor heating UFH.

Speed of installation

- A single layer instead of the multiple layer build up of traditional insulated concrete slabs.

- 1m3 can be mixed, pumped and placed in 5 minutes.

Easy to place

Lightweight. Fast and easy to place, spread level and finish.

Reduced material wastage

- Mix, pump and place on site. Make just enough material to suit requirements. No waste concrete to be disposed of.

- No large wasted insulation board off cuts left around site.

Rapid drying

- Dries at the rate of 1cm thickness per day.

- 10 times as fast as traditional screeds allowing trafficking and finishes to be applied much earlier.

Lightweight

- As little as 10% of the weight of concrete.

- With design mix densities between 215 and 365 kgs/m3 it is ideal for use in inter-tenancy floor slabs, balconies and flat roofs.

- Can be laid to falls

CE marking

From January 1st 2014.

Compliant with BS EN 16025-1:2103

Thermal and/or sound insulating products in building construction. Bound EPS ballastings. Requirements for factory premixed EPS dry plaster (British Standard)

Application

- An uncomplicated alternative to traditional insulated floor slab construction.

- Perfect insulated solution for replacement/retrofit floor slabs

- Ideal when used in conjuction with underfloor heating systems (UFH)

- Laid to falls insulation for roofing

- Laid to falls insulation for balcony upgrades

- Conservatory floors. Single pour. Fast curing. Solid construction. No bounce. Less echo

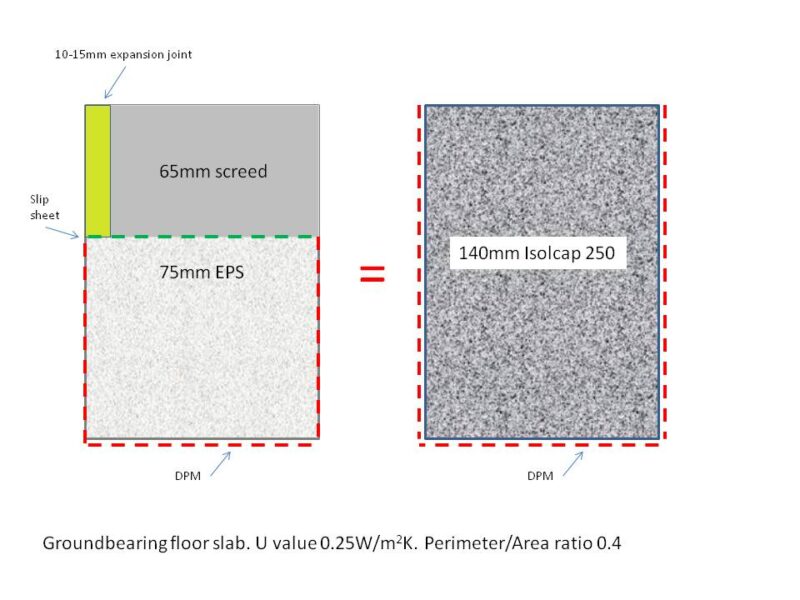

Comparative Build-Up: Classic Insulated Floor Slab vs. Isolcap 250 (TLA)

The above diagram shows on the left a 75mm thickness of EPS insulation topped with 65mm traditional sand/cement screed needed to achieve a U value of 0.25W/m2K for a ground bearing floor slab with a P/A ratio of 0.4

On the right the alternative Isolcap 250 (TLA) option that provides the same thermal performance but in one operation.

Both solutions are 140mm thick.

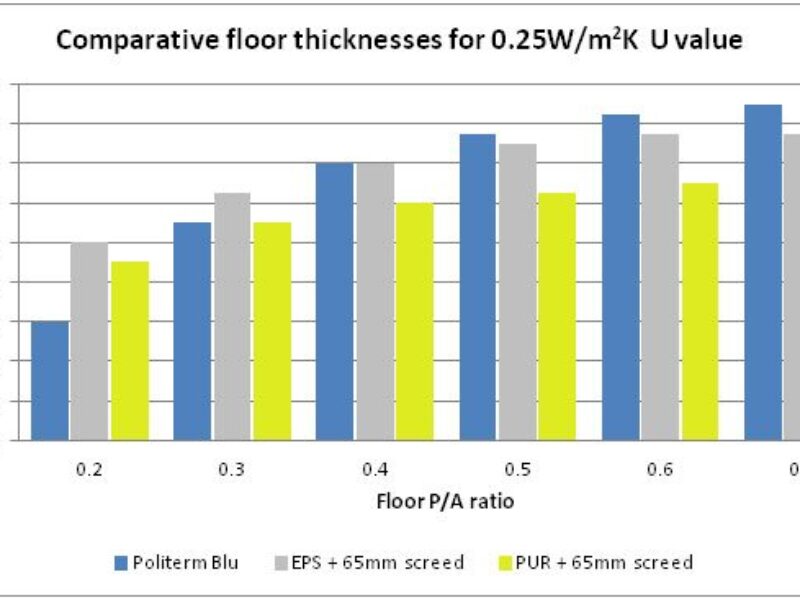

Lower P/A ratios as typified in terraced and semi detached houses require lesser thicknesses of Isolcap Blu screeds compared with the total thickness of conventional rigid insulation boards + sand cement screeds

The immediate advantages of the Isolcap 250 Thermal Lightweight Aggregate are:

Less sub base preparation. The Thermal Lightweight Aggregate (TLA) is poured directly onto the dpm and takes up any unevenness.

Less waste. No insulation boards to measure and cut. The exact amount of TLA required is mixed and poured. No large packs of insulation on site. No cutting. Less waste.

Faster to lay Insulation and screed combined in one operation

No perimeter movement joint required. Shrinkage/expansion is minimal in an Isolcap 250 (TLA) screed.

Rapid drying and curing. Cures and dries 10 times faster than traditional screeds. 1cm per day

Cost effective. Similar material costs but placed and dries in a far shorter time