Internal Wall Insulation

A high performance laminated board for insulating walls and ceilings. The product comprises Aerogel insulation bonded to magnesium board (MgO) to form a thermal laminate.

High Performance Aerogel Internal Wall insulation (IWI)

The high performance thermal insulation allows for ultra thin boards as little as 13mm thick

At Corepro Systems in Devon, we supply high performance thermal laminates to clients in London, Merseyside and across the UK. Contact us for more information.

CosyLine boards comprise 10mm aerogel insulation bonded to 3mm Magnesium Board (MgO) 1200 x 600mm

Designed for use in applications where improved thermal performance is required within limited available space.

Once installed CosyLine can be finished using paint or wallpaper

Applying 13mm thick CosyLine boards to a 9″ solid brick wall with a typical starting U value of around 2.1 W/m2K will reduce that U value to around 0.8 W/m2K, dependent on the wall structure.

A reduction in heat loss through the wall of over 60%

Installation and Site Handling

INSTALLATION GUIDELINES

PLANNING

• Ensure safe access and egress to the work area.

• Restrict access – control the number of people entering the work area.

• Close all unnecessary door openings and seal if possible.

• Plan how to carry out the work before beginning.

• Ensure substrates are level and suitable for fixing. Repair as necessary.

• Remove and relocate radiators, sockets and switches as necessary.

CUTTING THE BOARDS

Where possible it is recommended that the panels are cut outside.

If this is not possible care should be taken to provide adequate ventilation within the cutting area. Indoor cutting should be carried out over a plastic sheet to contain dust.

The use of mechanical cutters with dust extraction systems is recommended.

Goggles, gloves and a dust mask should always be worn during the cutting process.

Cutting is best done using a jigsaw or circular saw, whichever is most appropriate for the type of cut.

Before cutting, ensure the board is adequately supported.

Cuts should always be made from the internal face of the board (e.g. MgO side).

FIXING THE BOARDS

COSYLINE boards are fixed directly to a continuous solid substrate wall (masonry, plasterboard, lath & plaster) using Insta-stik foam adhesive.

Assemble the Insta-stik gun/straw apparatus following the manufacturer’s instructions.

Ensure the Insta-stik canister is well-shaken prior to use and that the substrate wall is as clean, dry and

dust-free as possible.

Select a lower corner of the wall to start the install from.

Place the first COSYLINE board on the floor with MgO-side facing down.

Starting 30mm away from a corner edge, depress the Insta-stik trigger and apply a bead of adhesive around the full perimeter of the board maintaining a 30mm distance from the edge.

Apply Insta-stik adhesive to the remainder of the board in an even ‘zigzag’ pattern.

Holding the board at the edges, carefully lift it into position onto the wall.

Ensure the adhesive side makes good contact with the substrate wall and that any cut-outs match.

Gently press the board against the wall, holding until sufficient adhesion occurs.

The first row of COSYLINE boards should be supported by existing skirting boards or a batten.

Continue this process, “tiling” the boards across the wall. COSYLINE boards can be installed staggered or in-line.

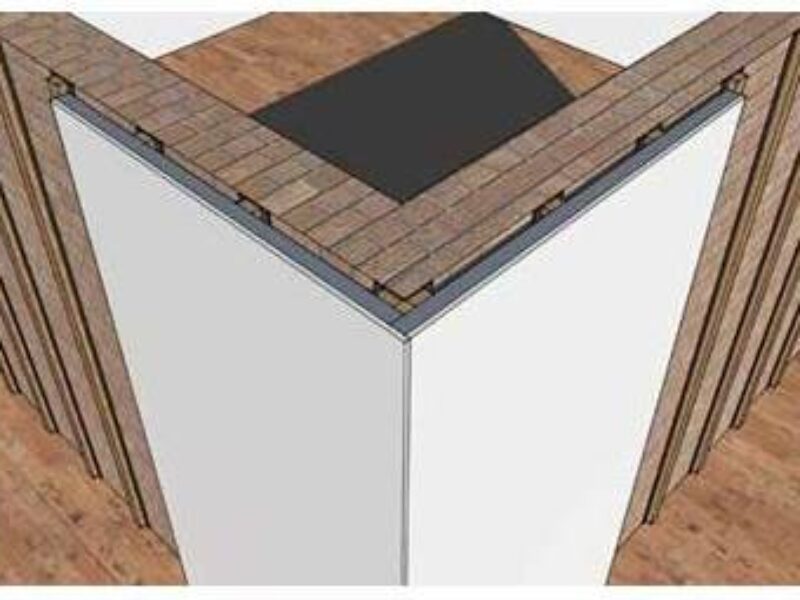

INTERNAL/EXTERNAL CORNERS

At corners, COSYLINE boards should be installed in such a way that the insulation layer overlaps to prevent a cold bridge at the junction.

For an external angle, the main wall insulation board should extend beyond the edge of the reveal by a distance equal to the insulation thickness. The edge of the insulation layer can then be trimmed at a distance equivalent to the main wall insulation thickness from the edge, allowing the two boards to intersect.

For internal angles, the facing should be trimmed back a distance equivalent to the insulation thickness, allowing the insulation layers to overlap.

After the boards are fixed in place, the joint should be taped and any gaps filled using a suitable filling compound. If additional strength is required at these edges, the use of a metal angle jointing strip should be considered.

JOINTING

Joints between adjacent COSYLINE boards are made in the conventional manner i.e. taped and filled with a gypsum based jointing compound. Before taping and filling, please ensure the board surfaces are free from dust (it may be necessary to use a vacuum cleaner), as excess dust on the surface may prevent adequate adhesion. Joints are then sanded as normal.

DECORATING

Wipe the COSYLINE panels with a dry cloth to remove any dust that may have accumulated on the surface during the installation process. Apply one coat of MgO Primer evenly over the entire upgraded wall area and allow to dry. A single coat of MgO Primer is often enough and will prepare the board to accept interior finishes e.g. paints, plasters, wallpaper, tile, etc.

SUBSEQUENT FIXINGS

It is not recommended to fix into COSYLINE alone. Any additional fixings that are required should be installed through the COSYLINE panels and securely into the substrate behind.